PRODUCT

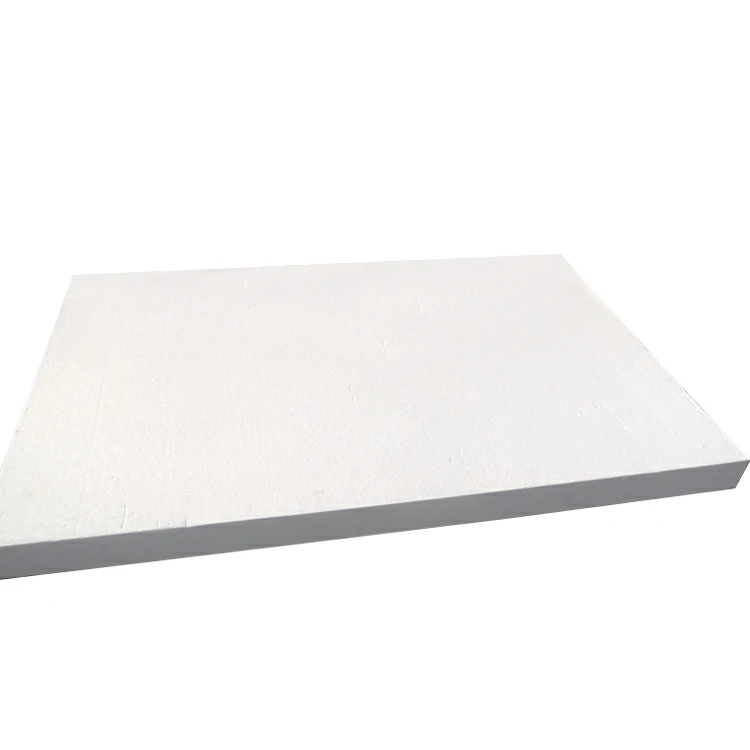

High Strength Ceramic Fiber Board Aluminium Silicate Board

1.Refractory lining for industrial furnaces in walls,roofs,doors,stacks,etc.

2.Combustion chamber liners,boilers and heaters

3.Back-up insulation for brick and monolithic refractories

4.Expansion joint boards

5.Barrier against flame or heat

6.Hot face layer for high velocity or abrasive furnace atmosphere

Product Description

Laurel ceramic fiber board is a lightweight refractory material processed with alumina-silica fibers for applications at temperatures up to 1430℃(2600℉)

Ceramic fiber board is a vacuum formed product that resists higher gas velocities than ceramic fiber blanket, it is ideal for furnace, boiler duct and stack lining due to its low thermal conductivity and low heat storage allowing shorter cycle times and quicker access for maintenance

Parameter

Features

1.Low thermal conductivity,saves fuel

2.Very low heat storage,faster heat and cool-down reducing cycle times

3.Ligh weight.replaces heavy back-up insulation.less steel required.

4.Excellent thermal shock resistance

5.Resistant to hot gas erosion

6.Resists most chemical attacks

7.Easy to cut, handle and install

8.Low sound transmission

9.Resists penetration by molten aluminum and other non-ferrous metals

10.Contains no asbestos

Picture