PRODUCT

Heat Insulation Calcium Silicate Pipes ASTM C610

1. Electrical equipment heat insulation

2. Metallurgical equipment heat insulation

3. Glass furnace equipment heat insulation

4. All kinds of furnace body heat insulation

5. Cement kiln heat insulation

6. Shipyard cabin heat insulation

7. Petrochemical industry heat insulation

Product Description

A free-flowing white powder is known as calcium silicate. A siliceous sedimentary rock, derived from naturally occurring limestone and diatomaceous earth. One of several compounds can result from reacting calcium oxide and silica in different ratios, including… Alite (Ca3SiO5) is formed by 3CaO·SiO2, (Ca2SiO4) by 2CaO·SiO2, (Ca3SiO7) by 3CaO·2SiO2, and wollastonite (CaSiO3) by CaO·SiO2. Its physical water absorption is high and its bulk density is low.

The primary ingredients for calcium silicate pipes are SiO2, CaO, and strengthening fibers. The stirring, heating, gelling, forming, pipe hardening and drying are the processes used to make the products. It is used in construction due to its light bulk weight, low thermal conductivity, and high bending and compressive strength. Petroleum, electric power, building partition walls, curtain walls, roofs, and thermal insulation for building envelopes.

Products Applications

- Insulation for electrical equipment

- Heat insulation for metallurgical equipment

- Heat insulation for glass furnace equipment

- Insulation for cabin heating in a shipyard

- Heat insulation for a cement kiln

- Heat insulation in the petrochemical industry

- All kinds of furnace body heat insulation

Producing Calcium Silicate Pipes – How It’s Done.

- The porous calcium silicate pipe, also referred to as asbestos-free pipe calcium silicate, is a type of fiber-reinforced calcium silicate pipe.

- It is produced by a series of procedures involving mixing, heating, gelling, molding, auto-claving, and drying.

- A novel insulation material known as calcium silicate pipe has been introduced and it is rigid in nature.

Parameter

Features

- The utilization of these backing insulation materials is clearly effective for conserving energy due to their ability to accumulate less heat and provide increased heat protection.

- The boards maintain good durability even after prolonged use as they don’t shrink, deform or produce powder and their insulation performance remains constant.

- Woodworking tools that are commonly used can be utilized to cut it into any desired shape with ease, and it can be combined with other materials by simply gluing and molding it.

- The calcium silicate tube possesses the highest rate strength among thermo inorganic materials, enabling significant reduction in the overall weight of kilns and stoves during the design phase.

- Environmental protection involves producing products that are free from corrosives and toxicity. These products should not emit exhaust gases or emit peculiar smells, especially under high temperatures. Additionally, they should not cause any harm or pollution to both the environment and human body. Such products can be classified as environmentally friendly.

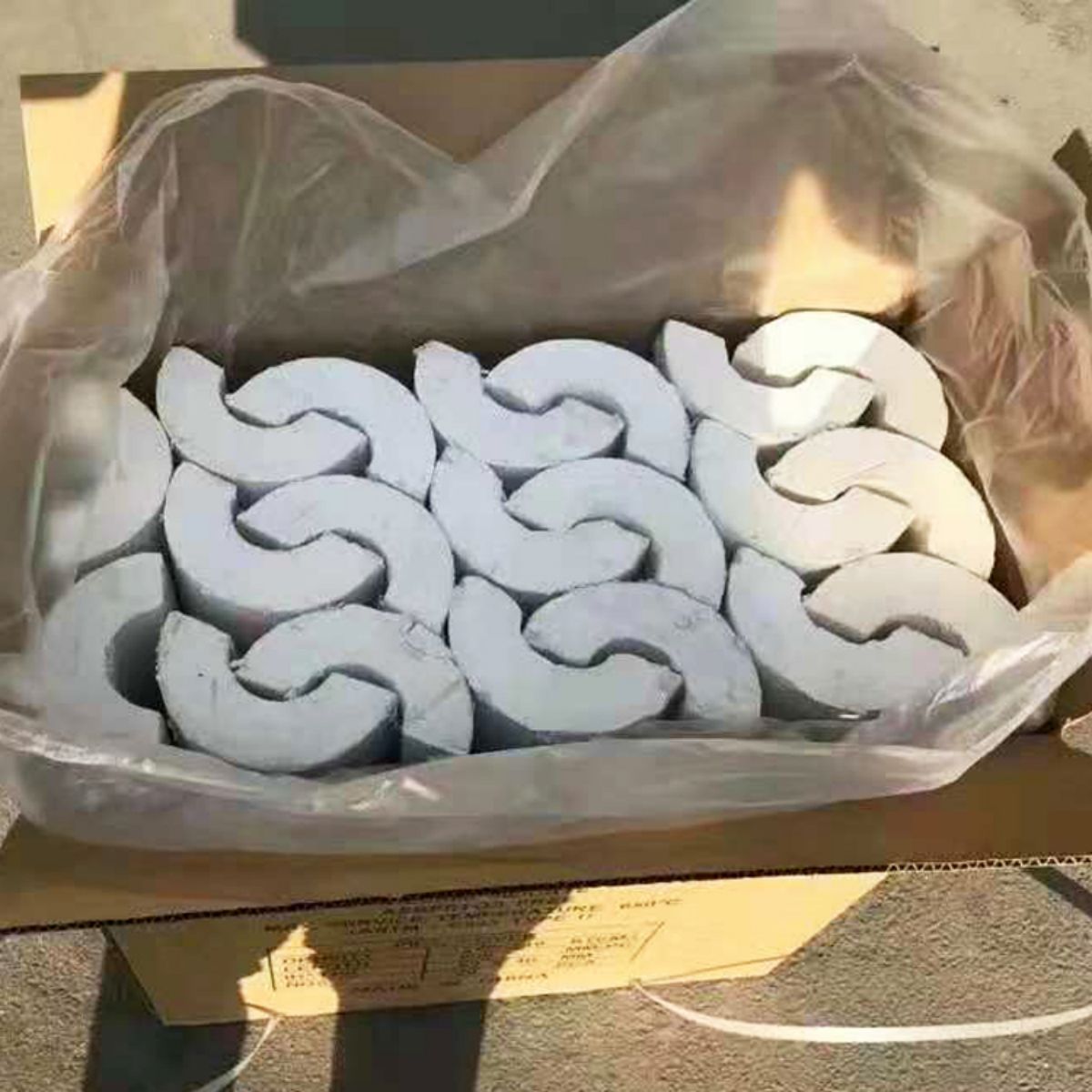

Picture